Catalog

-

Catalog

- Agriculture

- Apparel

- Automobiles & Motorcycles

- Beauty & Personal Care

- Business Services

- Chemicals

- Construction & Real Estate

- Consumer Electronics

- Electrical Equipment & Supplies

- Electronic Components & Supplies

- Energy

- Environment

- Excess Inventory

- Fashion Accessories

- Food & Beverage

- Furniture

- Gifts & Crafts

- Hardware

- Health & Medical

- Home & Garden

- Home Appliances

- Lights & Lighting

- Luggage, Bags & Cases

- Machinery, Hardware & Tools

- Measurement & Analysis Instruments

- Mechanical Parts & Fabrication Services

- Minerals & Metallurgy

- Office & School Supplies

- Packaging & Printing

- Rubber & Plastics

- Security & Protection

- Service Equipment

- Shoes & Accessories

- Sports & Entertainment

- Telecommunications

- Textiles & Leather Products

- Timepieces, Jewelry, Eyewear

- Tools

- Toys & Hobbies

- Transportation

Filters

Search

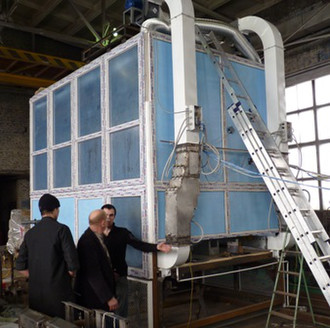

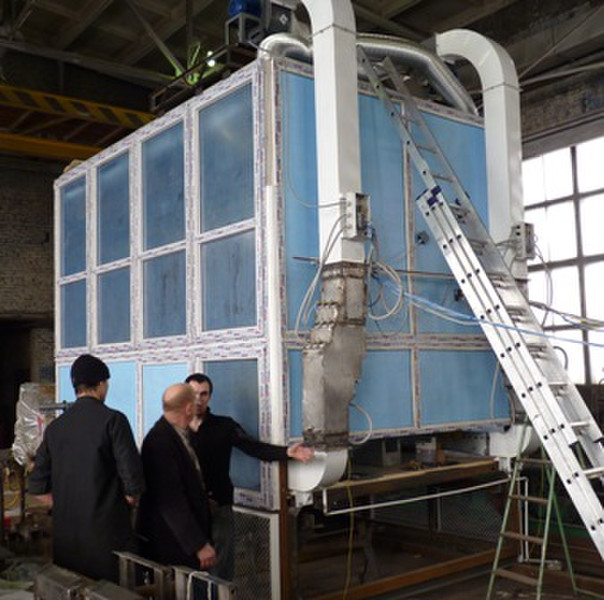

Installation of the climate

Condition:

new

original price: 0,00 RUB

Kemerovo, Russia

Minimal order:

1 Piece

ЕленаНиколаевна

Contact person

Basic Information

The installation of HVAC, is designed to provide and maintain the parameters of the plant environment inside the proofer or the camera when proofing dough pieces baked goods before baking.

Features:

The installed capacity of Heaters: 9 kW 13.5 kW

The volume of the proofing chamber (for single installation) of up to 20m3

The range of temperature in proofing Cabinet (camera) is adjusted manually and automatically: 35-40°C

The range of relative humidity in the proofing Cabinet (camera) is adjusted manually and automatically: 75-80%

The installation work is automated, setting the desired values of temperature and humidity is performed on the appropriate devices and then it is controlled by the current evidence. During operation, the controller maintains the preset parameters enabling and disabling heating elements and nozzle. The protection system includes a test device of an electric circuit and an overheat sensor that shuts down the installation in case of exceeding the permissible temperature of heating elements (for example, if the fan malfunctions, or if incorrect operation of the injector).

Payment term

Telegraphic transfer

-

Payment Methods

We accept: